EV battery makers race to develop cheaper cell materials

U.S. and European startups are racing to develop new batteries using two abundant, cheap materials – sodium and sulfur – that could ease looming supply bottlenecks and lead to mass-market electric vehicles (EVs).

Today's EVs run on lithium ion batteries — mostly made with lithium, cobalt, manganese and high-grade nickel, whose prices have soared.

The EVs of the future — those arriving after 2025 — could shift to sodium ion or lithium sulfur battery cells that could be up to two-thirds cheaper than today's lithium ion cells.

But their promise hinges on potential breakthroughs in electrochemistry. Newer battery chemistries have problems to be overcome. Sodium ion batteries don't yet store enough energy, while sulfur cells tend to corrode quickly and don't last long.

Still, more than a dozen start-ups have attracted millions of dollars in investment, as well as government grants, to develop new kinds of batteries.

The single most expensive element of an EV battery is the cathode, which accounts for up to a third of the cost of a battery cell.

Most EV batteries today use one of two types of cathodes: Nickel cobalt manganese (NCM) or lithium iron phosphate (LFP). NCM cathodes are capable of storing more energy, but use costly materials (nickel, cobalt). LFP cathodes typically don't hold as much energy, but they are safer and tend to be less expensive because they use materials that are more abundant.

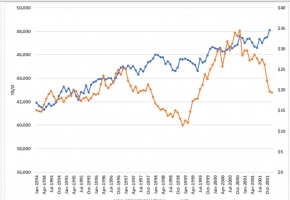

The cost of key cathode materials such as nickel and cobalt has skyrocketed over the past two years. That's why so many companies are hoping to substitute cheaper, more abundant materials such as sodium and sulfur, if their technical limitations can be overcome.

Source: Reuters